Early threshing machines

A summary of primary/historical source material relevant to the question of the adoption/diffusion of threshing machines. The themes of interest here are:

- Reliability (or lack thereof) of early threshing machines

- How the machines were constructed and how that relates to workmanship/quality

The entries here are in chronological order. I have modernized the spelling.

The Caledonian Mercury (Edinburgh, 26 Aug 1735)

Andrew Good Wright advertises threshing machines:

Those who want them, must send for them from Edinburgh, and a millwright to receive them, that he may know how to set them up; which any millwright will be able to do, after he has seen one going. … Millwrights recommended by gentlemen for their integrity, if they come to Edinburgh, and understand the machine, shall have liberty from the patentee to make them in the country.

Note that this is some 50 years before we have evidence of any threshing machine being successful or widely adopted.

The Virginia Gazette (Williamsburg, 19 Nov 1772)

An advertisement from John Hobday reads:

The subscriber having invented a cheap and simple machine for separating wheat from the straw, which will, with care, beat out a hundred and twenty bushels a day, with three horses, or in that proportion with a greater or less number, begs leave to inform the public that he proposes to get some gentlemen in every country to set on foot a subscription for raising such sums as they may think the invention of so useful a machine deserves. And he now takes this method of requesting the favor of all lovers of useful improvement to encourage and promote this; which he does assure them may be carried into execution by any tolerable carpenter, and the whole expense, if purchased, will not exceed fifteen pounds, and if made by gentlemens own servants will not cost twenty shillings. As soon as a sufficient sum is subscribed he will produce models, and lodge them in different parts of the country. This he hopes to be encouraged to do by the April general court next, that all the subscribers may have time to furnish themselves with the machine before harvest. He does not expect, or desire, to receive a shilling of the money subscribed till the October general court following, nor even then unless it shall appear that his machine deserves it. JOHN HOBDAY.

The Caledonian Mercury (Edinburgh, 6 Sep 1777)

Advertisement for a book, Clarke’s True Theory and Practice of Husbandry, which contains

full directions for making and managing a cheap and durable machine, for threshing corn, which may be worked by wind, water, horses, or men, to great advantage; as by its manner of threshing, more corn will be got from the straw, than by the present laborious way, and the expence will be much less.

The Leeds Intelligencer and Yorkshire General Advertiser (22 Feb 1796)

An advertisement for Jubb’s Patent Threshing Machine:

The above machine is made by John Jubb, millwright and machine-maker, of Leeds, the sole patentee, who will send it to any part of the kingdom, at the price of 25 guineas; the purchaser to pay the carriage, and expenses of setting it to work. The horse wheel, with the other motions, to carry the machine, from 20l. to 30l. according to the size of the machine or wheels required.

Any person at a distance, that chooses to make the wheel, etc., may be furnished with a plan of the millwright work, and method of setting the machine to work, (for one guinea) and the machine made at Leeds, taken to pieces, properly marked, and sent off either by land or water carriage, so that any workman may with ease put it together.

In general, around this time, there are many millwrights advertising threshing machines in Britain; this is just one example that is explicit about the mode of construction.

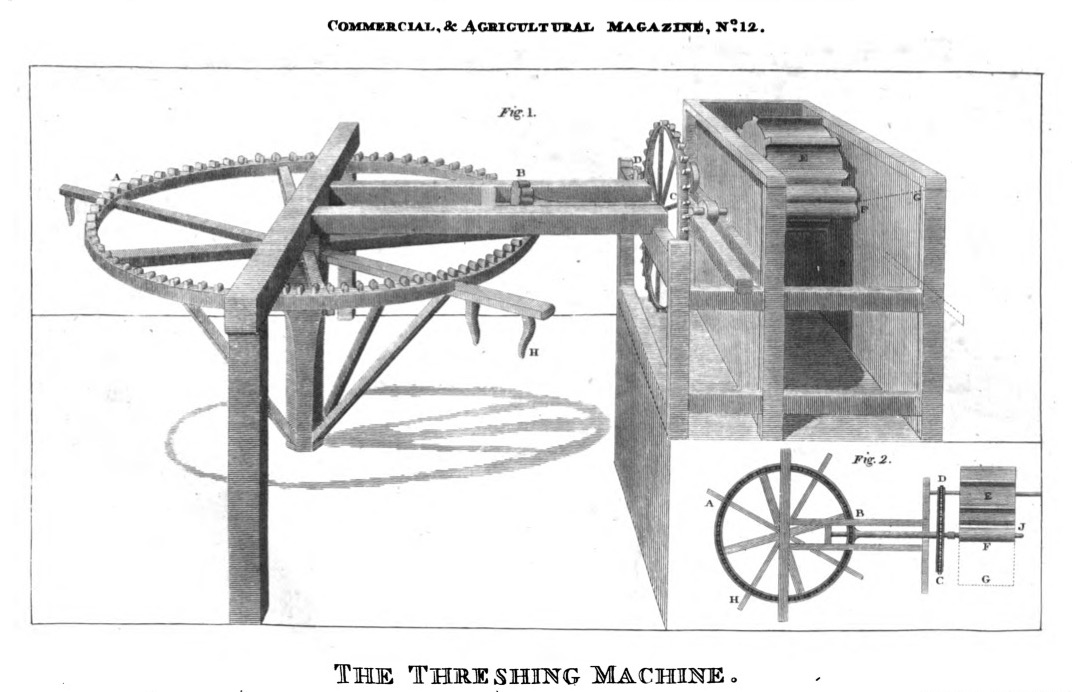

The Commercial, Agricultural & Manufacturer’s Magazine (London, 1800)

The threshing machine was clearly important by this time, because the preface of the entire volume mentions:

On the subject of the threshing machine we have bestowed much attention; it promises a diminution of the usual waste of corn by careless threshing. We have been promised additional information of this machine, and hope that the next year will see it adopted into general use.

The very first article covers the threshing machine, with a diagram and explanation of its working.

Here’s the key passage for the present inquiry:

An industrious workman, of the name of Stevenson, (foreman to the late Mr. Winlaw) has constructed almost all the threshing machines in England, and the facility with which his last made machines move by hand, and the length of time they continue to go after motion is imparted, is a sure warrant of accurate workmanship, and diminished friction. A material improvement (of this man’s invention) is the addition of iron plates on the surface of the beaters: hence,by two screws, the beater may be set at any distance from the rollers. His place of abode is No. 74, Margaret Street, Cavendish Square.

Later in the volume (p. 93), an Essex farmer says in a letter that he’s going to build a custom machine:

I have at length inspected one in a neighbouring county, which, with certain improvements suggested to me by an ingenious mill wright, I propose as my model. The expence, I am assured, is not to exceed one hundred and fifty pounds, everything complete, and the mill at work; however, I shall not be over rigid, or dissatisfied, granting it to extend somewhat farther.

R. Somerville, General View of the Agriculture of East Lothian (1805)

Chapter V, Implements of Husbandry, section 5, Implements for Separating the Grain from the Straw, Chaff, &c.

Reports on an early threshing machine attempt:

The first of these was invented by a Mr. Menzies… the machinery was driven by a water-wheel, which put in motion a number of flails of the same kind with those used in thrashing by the hand. Trials made with these machines were so far satisfactory, that a great deal of work was done in a given time, but, owing to the velocity required to do the work perfectly, they soon broke, and the invention fell into disgrace.

Another attempt is described in 1758, no information on what happened to it.

Then another attempt “about twenty years after,”

Their machine was so constructed as to act, by rubbing in place of beating out the grain. … Upon trial this machine was also found defective, as along with its doing very little work in a given time, it bruised the grain, and so materially hurt its appearance, as to lessen its value considerably in the market.

Says that the first successful machine was built in 1786 by “Mr. Mickle of Know Mill,” in other sources this name is usually spelled “Meikle”.

American Farmer (Baltimore, 11 Apr 1823)

An article on “Pope’s Threshing Machine” ends with a letter from Joseph Pope, Jr. (son of the deceased inventor), who states:

The hand machine can be constructed at little expense, the materials, including the shears, cost $13, and it can be made by a good workman, (say a joiner or carpenter) in 12 days.

The extra expense of the wheels for the application of horse power, does not exceed $20.

The National Gazette (Philadelphia, 19 May 1823)

Soon after, the following ad begins to appear, running regularly from May through October. It indicates that Pope was trying a new approach:

Having invested Messrs. S. V. Merrick & Co. Engine Manufacturers, Philadelphia, with the prvilege of making and selling my newly invented Patent Thrashing Machine, in any State south of New York, I recommend to all persons who wish to be furnished with a first rate warranted machine, to make application to them for obtaining one. JOSEPH POPE

Pope’s Patent Threshing Machine, constructed in the best manner may be obtained by applying to S. V. Merrick & Co., Philadelphia.

This appears to be Samuel Vaughan Merrick; here’s an 1856 ad for what became Merrick & Sons, Engineers & Machinists.

New England Farmer (Boston, 22 Sep 1826)

A brief report on a threshing machine demonstration:

The machine is simple; it can be made by any carpenter, with the aid of a little iron work.

New England Farmer (Boston, 27 Oct 1826)

A report on a Farmer’s Festival, “The Committee on Agricultural Inventions, Etc. Report”, states:

Mr. Joseph Pope exhibited a threshing machine… some improvements have been made, the beater being of iron in place of wood, the winnowing machine, and shears for cutting the straw wholly detached, and is now presented by Mr. Pope as an improved hand machine for threshing in the most thorough, cheap and expeditious manner, less complicated than any in use, and from the simplicity and strength of the machinery less likely to get out of order.

Genesee Farmer (Rochester, 30 Apr 1831)

An article on “Threshing Machines” says:

In the first place, before we come to remark upon the merits of those now in use, we would observe, that one of the great and principal causes of failures, in many kinds of machines, is the flimsy, cheap, and do-for the-present manner in which they are made. They are not unfrequently constructed by carpenters, or rather by those who are only an apology for a good one, and who could hardly construct a button to a barn-door, or as is frequently the case, by patentees, or their agents, a set of speculating cut-throats, alike ignorant of mechanical powers, of motion or matter, whose only talents consist in the rigmarole with which they recommend their wonderful discoveries.

By the operation of these causes the farmer often gets an ill-constructed, weak, and rickety machine, which needs wedging, nailing, and bracing, at every revolution, and as much power to drive it as would operate a run of mill stones; and I have known many tolerably good machines condemned, from having connected with it a weak, ill-contrived, and inaffective horse power.

The machinery that generates the motion, whether horse or water power, ought to be as well constructed, and of as good materials, as a flouring mill; and it is worse than useless to make the main wheel and pinion gearing of wood. Nothing but cast iron, and that of the softest and best kind, can be depended upon. — If the main and moving power is good, and of sufficient strength to apply as much power as is ever needed, almost any of the modern machines, if tolerably well made, will do a good business.

The writer goes on to describe many failed attempts he has witnessed over the years.

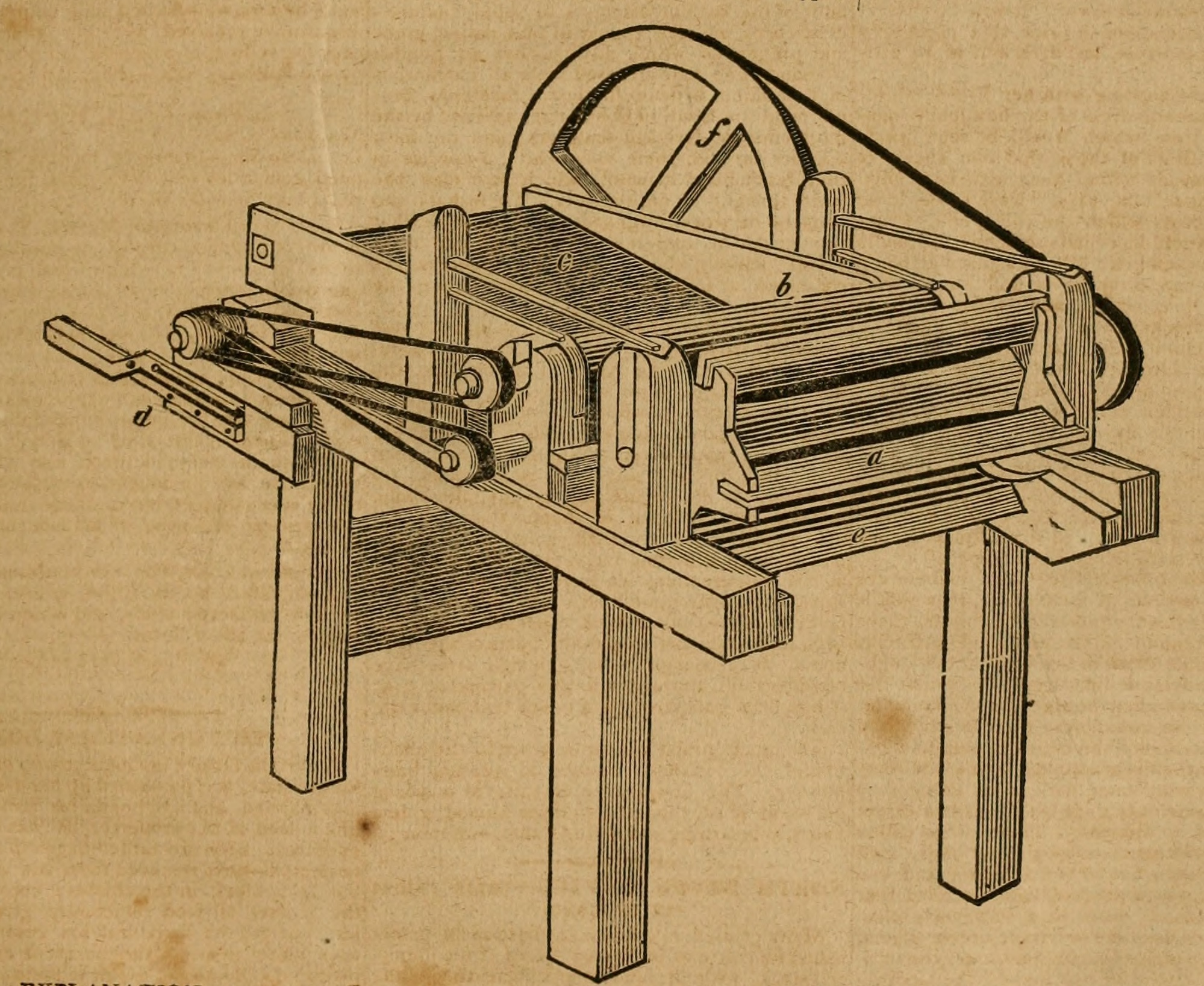

J. Allen Ransome, The Implements of Agriculture (1843)

Section VIII, The Thrashing-Machine, p. 137.

Mentions again Michael Menzies in 1732, and also:

… in 1753, Michael Sterling, a farmer in the parish of Dumblane, Perth, applied the principle of the mill in common use for hulling flax, to this purpose. … It was, however, found that this machine “broke off the ears of barley and wheat instead of clearing them of the grain, and that, at best, it was only fit for oats.”

After descriptions of many more attempts, only a few of which were successful, he says (153 ff.):

It has been urged against these machines, that they are apt to break the straw, and that they bruise and nib the barley so as to render it unfit for malting; but these faults are not so much attributable to the principles of the machines, as to the manner in which they are frequently turned out of the hands of the workman; and sometimes to the want of skill and judgment in the parties who have the management of them.

Many of these machines are made by persons who possess little claim to any mechanical knowledge, and who, purchasing the unfitted castings, by the help of village artisans, produce an imitation of those which are considered good. As the perfection of these machines must depend upon mathematical accuracy in the adjustment of all their parts, and in the truth and precision of their fittings, it is unreasonable to expect that this can be accomplished where no facilities exist beyond the forge and the work-bench; and hence arises a degree of discredit, which is unfairly thrown upon the principles upon which the machine is formed.